What role does the material of the polishing disc play in the adhesion and detachment behavior of the sandpaper particles?

Mar 23, 2025

Leave a message

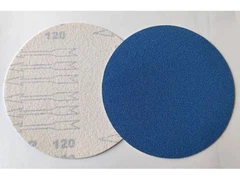

The impact of polishing disc materials on the adhesion of sandpaper particles

Roughness and adhesion: How rough the surface of the polishing disc is can affect how well the sandpaper particles stick. Usually, a rougher surface on the polishing disc gives more friction. That makes the sandpaper particles stick to the disc better and they don't fall off so easily.

Material hardness and wear: The hardness of the material the polishing disc is made of also has an effect on how the sandpaper particles stick. Harder materials, like metal polishing discs, give better support. That cuts down on the wear and falling off of the sandpaper particles when you're polishing.

Chemical compatibility: How well the material of the polishing disc and the sandpaper particles get along chemically is important too. If the material of the polishing disc works well with the sandpaper particles chemically, the particles stick to the disc easier and don't fall off when you're using it.

The impact of polishing disc materials on the falling off of sandpaper particles

Elasticity and buffering: How elastic the polishing disc is also makes a difference in how the sandpaper particles fall off. A polishing disc with the right amount of elasticity gives a better cushion when you're polishing. That lowers the chance of the sandpaper particles falling off because of too much impact.

Wear and renewal: How much the polishing disc wears also affects if the sandpaper particles fall off. As the polishing disc is used, its surface wears down. That changes how the sandpaper particles stick. If the material of the polishing disc doesn't wear well, the sandpaper particles are more likely to fall off because of the wear.

Temperature and humidity: The polishing disc makes heat when it's working and the humidity of where you're working can also affect how the sandpaper particles stick and fall off. Some materials for the polishing disc might make the sandpaper particles fall off more easily in a hot or humid place. So when you pick the material, you need to think about where you'll be working.

Examples and summary

Let's look at metal polishing discs and rubber polishing discs for example:

Metal polishing discs: They usually have a higher hardness. That gives better support and they don't wear out as easily. So the sandpaper particles stick to them better. But metal polishing discs aren't very elastic. They might hit the workpiece surface too hard when you're polishing.

Rubber polishing discs: They have better elasticity and buffering. That means less of the sandpaper particles fall off. But rubber polishing discs aren't as hard. They might wear out more easily after a long time of use.

Send Inquiry